A pathway for sustainable textile production : The Banswara ‘Higg’ experience

Leave a CommentDo you recall the excitement when a piece of clothing caught your eye while walking past a shop or surfing the internet? Your heart yearning to purchase it amidst a sea of online advertisements or busy lanes filled with the glitz and energy of vibrant garment sellers. No matter who we are or where we come from, we might all be able to relate to experiencing an emotional reaction to some or the other piece of clothing we were drawn to buy, either for ourselves or a loved one, at some point in our lives.

The textile and apparel sector is worth US $2.5 trillion worldwide and plays a significant role in a nation’s economy, employment generation and exports. The ministry of textiles annual report 2021-22 states India is the world’s 6th largest exporter of textiles. The Indian textile industry has a large unmatched raw material base and manufacturing strength across the value chain. The share of textile and apparel, including handicrafts, in India’s total exports stood at a significant 11.4% in 2020-21. It employs millions of people, which includes a large number of women from the rural population. For a textile industry manager, these statistics may look promising and can fuel the motivation to invest in expanding and propelling this economic growth. While clothing is a basic human need, it is more often than not a tool to feed capitalistic greed. A greed that feeds on socio-ecological injustice propagated by unmindful production and consumption practices. What are the injustices that are being alluded to? And what can be done to address them?

The injustices of the textile industry and a pathway to responsible production

While the textile and apparel industry might make economic sense, the ecological and social impact of the industry warrants scrutiny, given the industry’s multifaceted impact. During its life cycle, an apparel necessitates extracting, using, and disposing of resources which release toxic components into the environment. Marginalised sections of society are most vulnerable to the consequences of such insensitive apparel production practices. For instance, in Maharashtra, textile finishing colour tints the Ulhas and Waldhuni rivers blue. Another heartbreaking example is that of the Bandi River, affected by textile dye pollution, which flows through the Pali district in Rajasthan. River water testing revealed that chemicals from the Bandi had contaminated wells and hampered farming operations within a three-kilometre radius. These atrocities are evident in other countries too. A prominent example is that of the Kantamanto market in Ghana, which acts as a dumping ground for used clothing of the global north, disrupting the local textile industry and polluting the coastlines with unusable waste clothing. Incessant and mindless mass apparel production activities can therefore exacerbate the contamination of life-sustaining ecosystems, human rights abuses, and climatic disasters.

Growing public awareness and social cognisance about the environment are compelling the textile industry to produce environmentally friendly products. Consequently, many businesses and organisations are now focusing on environmentally responsible production methods. The Sustainable Apparel Coalition (SAC) is one such global, multi-stakeholder non-profit alliance aimed at supporting producers’ consumers and other stakeholders to move towards sustainability. It comprises over 250 prominent clothing, footwear, textile businesses, retailers, suppliers, service providers, trade associations, non-profits, NGOs, and academic institutions aiming to decrease environmental impact and promote social justice throughout the global value chain. The SAC created the ‘Higg Index’, a set of tools that standardise value chain sustainability assessments for all industry players.

Higg Index : An overview

The Higg Index helps stakeholders such as retailers, consumer goods brands, manufacturers, NGOs, governments and consumers to identify pathways to improve their existing practices and transition towards sustainable choices at an individual and collective level. It comprises a core set of five tools that together assess the value chain’s social and environmental performance and the product’s environmental impacts. These tools assess the environmental and social labour implications across the value chain. With this data, the sector can identify hotspots, continually improve sustainability performance, and achieve public demand for environmental and social transparency. The methodologies of the Higg Index have been developed over a decade in collaboration with SAC members, consultants, stakeholders, and industry experts.

The Higg tools include :

- Higg Facility Environmental Module (FEM),

- Higg Facility Social & Labor Module (FSLM),

- Higg Brand & Retail Module (BRM),

- Higg Materials Sustainability Index (MSI), and

- Higg Product Module (PM)

The following sections elaborate on the Higg Index evaluation process for Banswara Syntex. Banswara Syntex is a vertically integrated textile mill that produces high-quality yarn, fabric and garments. The organisation embarked on the sustainable production journey with the motivation to achieve science-based targets (SBTs) for textile industries. The targets are aimed at achieving absolute reductions of climate pollution and environmental harm, irrespective of economic growth (in terms of revenue or quantity of product produced annually). cBalance supported Banswara Syntex Ltd in using the Higg Index tool as part of this effort. The Higg Facility Environmental Module was considered best suited to support Banswara Syntex’s journey towards sustainability.

The Higg Facility Environmental Module

The Higg Facility Environment (FEM) module gives a comprehensive view of a facility’s sustainability performance. It facilitates assessing water use, waste management, and chemical management, among other relevant sustainability parameters. It has robust, standardised assessment parameters, which gives it an edge over the Life cycle assessment (LCA) tool. In addition, FEM provides a much broader scope of assessment as compared to carbon footprinting which is limited only to studying GHG emissions. Overall, it helps all industry players standardise value chain sustainability measures. The obtained data aids in finding hotspots for improving sustainability performance. It informs manufacturers, brands, and retailers about the environmental performance of their individual facilities, empowering them to scale sustainability improvements besides offering a clear picture of a facility’s environmental consequences. It assists in identifying and prioritising prospects for performance enhancement.

For the Banswara project, the Higg FEM assessed the following parameters:

- Site information and permits

- Environmental Management Systems

- Energy Use and Greenhouse Gas Emissions

- Water Use

- Wastewater

- Emissions to Air (If Applicable)

- Waste Management

- Chemical Management

Except for the site-information and permits parameters, each parameter has questions structured in a three-level format (Levels 1, 2, and 3) that represent general thresholds of good, better, and best environmental practises.

As part of this study, responses are analysed, and a score is allocated for each parameter according to levels. Based on this, total points are calculated by adding scores of all three levels for each parameter.

The Banswara Syntex Higg Experience

Recommendations for enhanced environmental responsibility were suggested by cBalance based on Banswaras’ Higg Scores for different subsections of the Higg FEM. Besides this, impact reduction recommendations beyond Higg parameters and other relevant socio-ecological impact reduction mechanisms were suggested to ensure accountability for environmental impacts emerging from the textile plants’ activities. While all parameters of the FEM are relevant, this article focuses on only the ‘Energy’ parameter of the Banswara Higg exercise in the interest of providing a basic understanding of the Higg assessment at a glance.

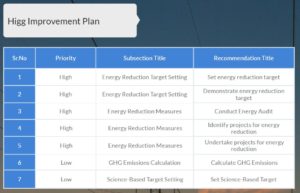

Banswara scored 80/100 for its energy-related practices. An indication of the facility’s progress at implementing a successful energy program. While good energy management provides significant benefits, including cost savings and efficiency, it requires adequate organisational focus and resources to correctly implement and be successful while reducing the impact on the environment. cBalance’s recommendations to Banswara based on its energy score are indicated in the image below :

Recommendations for other parameters, such as water, wastewater, etc. were shared as relevant based on the Higgs assessment. A detailed report which elaborates on all parameters and recommendations can be found here.

Way Forward

The textile industry is deeply intertwined with our lives, and the injustices it propels compel us to address the consequences of profit-driven human production practices that have altered the earth’s ecosystems to the point that our survival appears to be in jeopardy due to changes that are becoming increasingly onerous to reverse every day. Coalitions like SAC bring much-needed hope and motivation for mindful textile production. It provokes questions of ecological and social balance and encourages textile industries to reimagine and adopt sustainable production practices.

Healthy and responsible textile production calls for – consumers who purchase wisely and hold corporations accountable for unjust production practices, responsible textile-producing entities who look beyond profit and governments who overthrow unhealthy development agendas and move towards supporting and encouraging production and consumption practices that truly serve the planet’s needs.

As Wendell Berry, a writer, farmer and environmental activist, reminds us,

It is, therefore, only through a collaborative effort of mindful living that we can safeguard our planet’s present and future and manifest a just and habitable world for all.

References

- https://globaledge.msu.edu/industries/apparel-and-textiles/background

- https://www.britannica.com/topic/textile

- Political Components of the Industrial Revolution: Parliament and the English Cotton Textile Industry, 1660-1774, Patrick O’Brien, Trevor Griffiths and Philip Hunt

- https://www.greenofchange.com/textile-pollution

- Toprak T, Anis P. Textile industry’s environmental effects and approaching cleaner production and sustainability, an overview.

- The Environmental Disaster that is Fuelled by Used Clothes and Fast Fashion | Foreign Correspondent

- How 7.5 Million Pounds Of Donated Clothes End Up At A Market In Ghana Every Week | World Wide Waste

- The Higg Index – Sustainable Apparel Coalition

- https://theworld.org/stories/2021-10-18/how-west-s-obsession-fast-fashion-compounds-environmental-nightmare-ghana

- https://globalgreen.news/ghana-toxic-fumes-from-old-clothes-pollute-the-air/

- http://texmin.nic.in/sites/default/files/AR_Ministry_of_Textiles_%202021-22_Eng.pdf

- https://www.hindustantimes.com/mumbai-news/textile-finishing-dye-turns-ulhas-river-water-turquoise/story-vPDfGlKIAQGNS0g5yRAHUO.html

- https://www.fabricoftheworld.com/post/noyyal-and-bandi-rivers-shocking-cases-of-the-textile-industry-s-pollution-in-india

- https://sdgs.un.org/goals/goal12

- https://ajssr.springeropen.com/articles/10.1186/s41180-020-0032-8#Tab4

Author : Vipul Patil

Editor : Vinita Rodrigues