Reducing Gits Foods’ Footprint

Posted OnAlthough it has been around for a couple of decades, the life cycle assessment (LCA) is a tool increasingly being used by businesses to measure the environmental impact of their operations, products, and decisions. The LCA is defined by the USEPA as “a ‘cradle-to-grave’ approach for assessing industrial systems…[that] evaluates all stages of a product’s life from the perspective that they are interdependent, meaning that one operation leads to the next.” In recent years, LCAs have been performed at the organizational level, but typically they are used for individual products and decisions. An LCA measures everything that goes into a product from its creation to its disposal, all of the inputs and processes used every step of the way from the manufacturing of the parts used in its assembly to the chemicals added in its production to the electricity consumed during its use. (Of course such measurements could continue infinitely, so the LCA practitioner defines the boundaries during the first stage of the LCA.) LCAs are sometimes used to evaluate the outcomes of two different choices in a product’s design, e.g. using cotton that is either knit or woven in manufacturing a T-shirt, and can be extremely useful for businesses or individuals who seek to minimize their ecological footprint.

Here cBalance used the LCA to compare the environmental impacts of different food products manufactured by Gits Food, a business established in 1963 that pioneered convenience processed food in India and was one of the first food product manufacturing companies in India to have obtained ISO 9001 – 2008 (Quality Standard) and ISO 22000 (Food safety). Already a leader in terms of quality and credentials, they are looking to incorporate the principles of sustainability into their operations. ‘Gulab Jamun’, ‘Khaman Dhokla’, ‘Idli,’ and ‘Dosai’ were the products chosen for this study, and the LCA only analyzed GHG emissions.

Scope:

The scope of the study included the following life cycle stages of the products’ lives:

-Production

-Supply chain

-Upstream transport and distribution

-Waste

-Travel and commute

-Downstream logistics

-Use of sold products

-End of life treatment

Hotspot Analysis:

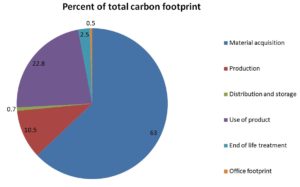

The stage with far and away the greatest impact is the raw material acquisition stage, contributing, on average, 63% of total GHG emissions. In line with the Greenhouse Gas Protocol classification, this stage also includes emissions from delivery of raw materials from suppliers and marine and road distribution for export, while ‘distribution and storage’ comprises road shipment from warehouses to retail outlets. Since raw materials have the biggest impact, efforts to reduce GHG emissions should focus on this area. The production stage contributed, on average, to 10% of the total GHG emissions, distribution and storage 0.7%, use of product 22.8%, end-of-life treatment 2.5%, and office footprint 0.5%. The average GHG emissions per packet of product was 648 grams, and the average GHG emissions per kilo of product was 2.53 kilograms.

Subsequent proposed steps:

-Internal training workshop to engage employees and the suppliers on issues related to sustainability and reduction of ecological footprint through sustainable operations and food sourcing practices

-Engage in smart consumer communication on the study, conveying on what can be done individually at home to reduce the footprint

-Industry-wide events to promote environmental awareness from food suppliers to manufacturers

Products’ Greenhouse Gas emissions:

Emissions per packet of product in grams of CO2e:

-594 Gulab Jamun

-620 Khaman Dhokl

-687 Dosai

-692 Idli

Solutions:

There are many ways that food companies can reduce their carbon (and overall ecological) footprint. Here are some recommendations:

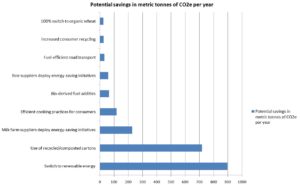

-Switch to renewable energy supply

-Collaborate with milk farmers to implement energy efficiency measures at their farms

-Encourage consumers to use efficient cooking practices

-Switch to bio-derived fuel additives in vehicles

-Increase use of fuel-efficient vehicles

-The potential for reduction of greenhouse gas emissions across the four products is 2000 metric tons!

Conclusion:

Businesses can leverage product LCA outcomes in a number of ways. Most obviously, businesses can use these studies to reduce their carbon (and ecological) footprints through internal operational practices, collaboration with suppliers, and communication to customers. These studies can also be used to acknowledge a business’s eco-credentials through ecolabel certification schemes. And businesses can spread these messages across the industry through stakeholder events and workshops. Finally, under best-case circumstances, LCA data can be used to benchmark performance against other products domestically and internationally, providing customers with objective data on the environmental performance of the products they’re considering purchasing. LCAs can be extremely useful tools for organizations and individuals to reduce their environmental impacts, and hopefully they continue to become more widespread.

The original study can be read here.