Carbon emissions in the Cement sector in India

INTRODUCTION TO CARBON EMISSIONS IN THE CEMENT SECTOR IN INDIA:

Cement as a commodity plays a vital role in the growth of a nation since it is an essential raw material for concrete which is a key raw material in key sectors like infrastructure, construction, commercial and residential real estate. Globally, cement contributes about 5% of the total CO2 emissions. Concrete is the second most consumed substance on Earth after water. On average, each year, three tons of concrete are consumed by every person on the planet. In India, the cement sector is one of the prominent contributors to conventional as well as GHG emissions. Although there is no statutory obligation on companies to measure and report total air emissions in India, the preparation of air emission inventories can be useful in internal company benchmarking, public reporting, product profiles, and emerging emissions trading. In the near future, it is also possible that such inventories will encourage voluntary actions to promote energy efficiency and GHG emissions mitigations, especially in large, organized industrial sectors like cement

INDIAN CEMENT SECTOR AT A GLANCE:

India stands second in the cement production in world after China. The total installed capacity of India in 2009-10 was 236 MT in 2009–2010. In same year the cement production for India was 200.7 MT.

PROCESS DESCRIPTION:

Carbon dioxide (CO2) is emitted from both the chemical process and energy consumption associated with the manufacturing of cement. During calcination or calcining, calcium carbonate (CaCO3)(limestone) is heated in a cement kiln to form lime, a process that emits CO2 as a byproduct. This accounts for about 50% of all emissions from cement production. The resulting lime reacts in the kiln with silica, aluminum, and iron oxides present in the raw material to produce clinker. Clinker, an intermediate product, is mixed with a small amount of gypsum and/or anhydrite to make Portland cement. Indirect emissions from the burning of fossil fuels used to heat the kiln account for about 40% of emissions from cement. Finally, electricity used to power additional machinery and the transportation of cement account for the remaining 5-10% of the industry’s emissions. (Rubenstein)

SCOPE AND METHODOLOGY FOR CEMENT SECTOR INVENTORY:-

SCOPE

For this study 51 cement producing Indian companies have been analyzed. ‘Carbon emissions in the Cement sector in India’ have been calculated per ton of cement produced by each company from data available in their annual reports using the process shown in the diagram below. Emissions per ton of cement produced is known as the emission intensity of the company or also referred to as the emission factor. The following Scope 1, Scope 2 and Scope 3 activities as defined are taken into consideration.

FORMULA

Emission factor (TCO2e/Ton cement produced) = Total emissions in FY / Total amount of cement produced in FY

METHODOLOGY

- Energy fuels comprise of various fossil fuels, wood, municipal waste, peat fuels.

- Electricity purchased is the quantity of electricity purchased by a company from the grid.

- Captive power generation is the self generation of electricity for meeting internal requirements. A company can produce electricity through various technologies like diesel generator, gas generator, steam generator etc. Depending on the technology and the fossil fuel used emissions from captive power generation is calculated.

- In cases where company specific captive generation emission factors are not available an India average for that particular technology has been used

- Non energy emissions are emissions resulting from the chemical processing of certain materials such as limestone and is obtained from one of the following sources of data as per the IPCC/GHG Protocol guidelines : clinker production, limestone production and cement production

- Emissions from Raw material purchased include Scope 3 emissions which are attributed to a company when either limestone or clinker is purchased for use as a raw material in cement manufacturing.

RESULTS:

| Company Name | Actual Production in ‘000 Tons | Total CO2e in ‘000 tonnes | TCO2e/ton cement production | Percentage intensity related to India Average Emission factor |

| A C C |

Ltd.

21369.00

17522.58

0.82

0.96

Ambuja Cements Ltd.

18828.45

13368.20

0.71

0.83

Andhra Cements Ltd.

990.94

693.66

0.7

0.82

Anjani Portland Cement Ltd.

497.72

408.13

0.82

0.96

Barak Valley Cements Ltd.

207.92

176.73

0.85

1.00

Bheema Cements Ltd.

251.60

183.67

0.73

0.85

Binani Cement Ltd.

5280.00

4012.80

0.76

0.89

Birla Corporation Ltd.

5698.00

4615.38

0.81

0.95

Burnpur Cement Ltd.

74.92

39.71

0.53

0.62

Cement Corpn. Of India Ltd.

968.23

1103.78

1.14

1.33

Cement International Ltd.

78.73

37.79

0.48

0.56

Cement Manufacturing Co. Ltd.

401.41

622.19

1.55

1.81

Century Textiles & Inds. Ltd.

7583.22

7507.38

0.99

1.16

Chettinad Cement Corpn. Ltd.

4003.47

2882.50

0.72

0.84

Cochin Cements Ltd.

58.52

26.92

0.46

0.54

Dalmia

cement (Bharat) Ltd.

4074.00

3585.12

0.88

1.03

Deccan Cements Ltd.

1096.95

1217.61

1.11

1.30

Gujarat Sidhee Cement Ltd.

2034.19

2196.93

1.08

1.26

Heidelberg Cement India Ltd.

2660.67

1676.22

0.63

0.74

Hemadri Cements Ltd.

203.64

238.26

1.17

1.37

India Cements Ltd.

10494.00

8710.02

0.83

0.97

J K Cement Ltd.

4586.51

4540.64

0.99

1.16

J K Lakshmi Cement Ltd.

4156.76

3283.84

0.79

0.92

K C P Ltd.

807.65

654.19

0.81

0.95

Kakatiya Cement Sugar & Inds. Ltd.

258.86

308.05

1.19

1.39

Kalyanpur Cements Ltd.

676.00

594.88

0.88

1.03

Keerthi Industries Ltd.

280.11

296.91

1.06

1.24

Lafarge India Pvt. Ltd.

7851.20

4789.23

0.61

0.71

Madras Cements Ltd.

8030.00

6343.70

0.79

0.92

Mangalam Cement Ltd.

1637.00

1718.85

1.05

1.23

Meghalaya Cement Ltd.

555.98

489.26

0.88

1.03

My Home Inds. Ltd.

2984.34

2327.79

0.78

0.91

N C L Industries Ltd.

590.14

714.07

1.21

1.42

O C L India Ltd.

3035.00

1821.00

0.6

0.70

Orient Paper & Inds. Ltd.

3056.03

2750.43

0.9

1.05

Panyam Cements & Mineral Inds. Ltd.

433.03

506.65

1.17

1.37

Penna Cement Inds. Ltd.

4088.77

3679.89

0.9

1.05

Prism Cement Ltd.

2568.32

2439.90

0.95

1.11

Rain Commodities Ltd.

2372.30

1992.73

0.84

0.98

Rishi Cement Co. Ltd.

1.74

2.92

1.68

1.97

Sagar Cements Ltd.

1120.35

1557.29

1.39

1.63

Sainik Finance & Inds. Ltd.

37.61

32.72

0.87

1.02

Samruddhi Cement Ltd. [Merged]

10121.95

10020.73

0.99

1.16

Sanghi Industries Ltd.

1828.17

1919.58

1.05

1.23

Saurashtra Cement Ltd.

1285.92

1337.35

1.04

1.22

Shiva Cement

Ltd.

98.47

88.62

0.9

1.05

Shree Cement Ltd.

9371.92

7684.97

0.82

0.96

Shree Digvijay Cement Co. Ltd.

1010.66

899.49

0.89

1.04

Ultratech Cement Ltd.

17639.00

17991.78

1.02

1.19

Vinay Cements Ltd.

97.69

137.74

1.41

1.65

Zuari Cement Ltd.

3195.20

2556.16

0.8

0.94

Sum

180632.25

154306.96

0.85

ANALYSIS OF CARBON EMISSIONS IN THE CEMENT SECTOR IN INDIA:

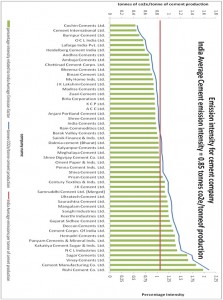

The graph below shows us the emissions per ton of cement produced for each company as well as the emission intensity of the various companies as compared to the India average of 0.85 TCO2e/ ton of cement produced. We can see that about 55% of the companies i.e. 28 out of 51 have emission intensities higher than the India average. Cochin Cement Ltd. has the lowest emission factor of 0.46 TCO2e/ton while the company with the highest factor is Rishi Cement Ltd. at 2.92 TCO2e/Ton cement. The range of the intensity with respect to the average varies from 0.54 of Cochin Cement Ltd. to 1.97 of Rishi Cement Ltd.

Figure 1: Emission intensities of companies in the cement sector in India

DISTRIBUTION OF GHG INTENSITIES OF COMPANIES IN THE SECTOR:-

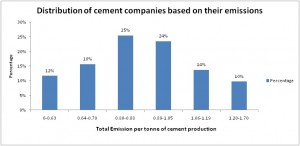

The distribution of emission intensities of the companies analyzed is shown below:

Figure 2: Distribution of emission intensities of companies in the cement sector in India

Figure 2: Distribution of emission intensities of companies in the cement sector in India

As visible in the graph above about half of the 51 companies have emission intensities in the medium range. There is quite an even distribution of companies with about a quarter in the above average range and a quarter in the below average range. The 12% of companies in the first bar can be termed as sector leader and set the benchmark for the rest of the industry. Second bar are above average but need some process related interventions to improve efficiency. The laggards are companies in need of major technology advances to improve efficiency and reduce emissions. Such a chart can help policy makers design specific policy initiatives to cater to companies in each range as well provide prioritize incentives based on the quantum of distribution.

METHODS FOR CARBON MITIGATION IN THE CEMENT INDUSTRY:-

Indirect emissions from burning fossil fuels to heat the kiln can be reduced by switching to such as natural gas, biomass and waste-derived fuels. These less carbon-intensive fuels could help reduce almost a quarter of overall cement emissions from 2006 levels by 2050.

Increasing efficiency of the production process so as to reduce the demand for fuel through technical and mechanical improvements will also help drastically reduce emissions. Steps such as switching from inefficienct wet ils to dry ones or regular preventive maintenance could help achieve emission reductions of upto 40%.

Reducing emissions from the calcination process means looking for an alternative to limestone. Blended cement made up primarily of coal fly ash and blast furnace slag replaces some of the limestone-based clinker with other materials. This could help reduce CO2 emissions by as much as 20%, but widespread use of blended cement is limited by other environmental regulations as these substitutes can contain toxic heavy metals; the limited availability of substitute material; as well as some building code restrictions since blended cement can take longer to set.

The final method of containing CO2 emissions is after they are produced through carbon capture and storage. In addition to traditional CCS methods, which are already employed in some power plants around the world, concrete producers can explore using their own product as a sink for CO2. Through the process of accelerated carbonation, CO2 penetrates concrete and reacts with calcium hydroxide in the presence of water to form calcium carbonate; the result is stable, long-term CO2 storage. As a mitigation technology, accelerated carbonation can be achieved by exposing freshly mixed concrete to flue gases with high CO2 concentrations. (Rubenstein)

CONCLUSION:-

There are 28 companies out of 51 in the cement sector whose emission factor is more than the India average per ton produced. If all of these companies improve their efficiency using the various methods mentioned above, to atleast the Indian average there will be a savings of upto 10.41 Million TCO2e. In a potential best case scenario, if all the other 50 companies perform atleast as well as the best in class, i.e Cochin Cement ltd. which has an emission intensity of 0.46 TCO2e/ton of cement produced, approximately 71.21 Million TCO2e can be saved. Such sector specific and company specific understanding of GHG intensities can be a useful tool for policy making in order to frame direct and target based incentives which will be necessary if India is to achieve its goal of 20-25% emission reduction over 2005 levels by 2020.

GLOSSARY

1) Scope 1: Direct air emissions from sources that are owned or controlled by the company These include direct process emissions (e.g. calcination of raw materials), direct stationary combustion in furnaces, diesel generator sets, etc., from fossil fuels, and mobile emissions from company-owned vehicles.

2) Scope 2: Indirect air emissions from the generation of purchased electricity consumed by the company 3) Scope 3: Other indirect air emissions from sources not owned or controlled by the facility like extraction and production of purchased materials, transportation of purchased fuels, clinker imports, and use of sold products and services

REFERENCES

- (The Energy and Resources Institute (TERI),USEPA, 2005 • http://www.ibef.org/download/Cement_270111.pdf

- http://www.ibef.org/download/Cement_270111.pdf

- Calculating CO2 process emissions from Cement Production (Cement-based Methodology), Guide to calculation worksheet (October 2001) • Rubenstein, Madeleine – http://blogs.ei.columbia.edu/